1. Introduction: Mastering Machine Embroidery Design Creation

Machine embroidery designs are where art meets technology, transforming your creative vision into precise, stitched masterpieces. Whether you’re a curious beginner or a seasoned embroidery pro, understanding the digitization process is essential for turning images into machine-ready embroidery files. In this guide, we’ll break down the step-by-step digitizing workflow, compare top software options, and share practical optimization techniques that ensure your designs stitch out beautifully—no matter the fabric or project complexity. From troubleshooting common pitfalls to leveraging free learning resources, this comprehensive guide will empower you to elevate your embroidery results and streamline your creative process.

Table of Contents

- 1. Introduction: Mastering Machine Embroidery Design Creation

- 2. Step-by-Step Digitization Process: From Image to Embroidery File

- 3. Software Showdown: Top Digitizing Tools Compared

- 4. Design Optimization Techniques for Professional Results

- 5. Fabric-Specific Adaptation Strategies

- 6. Troubleshooting Common Machine Embroidery Issues

- 7. Advanced Manual Digitizing Workflows

- 8. Conclusion: Your Path to Embroidery Design Mastery

- 9. Frequently Asked Questions (FAQ)

2. Step-by-Step Digitization Process: From Image to Embroidery File

Digitizing embroidery designs is both an art and a science. Let’s walk through the essential steps that bridge the gap between your original artwork and a flawless machine-stitched result.

2.1 Preparing Designs: Image Import and Optimization

Every great embroidery design starts with a well-prepared image. Begin by selecting high-contrast, clear artwork—think bold lines and minimal gradients. High-resolution images are your friend, as they make it easier for digitizing software to interpret details accurately. If you’re working with digital files, vector formats (like SVG or AI) are ideal because they scale without losing quality. Raster images (such as PNG or JPEG) can work too, but should be at least 300 DPI to maintain crisp edges.

Before importing your image into embroidery software, clean up any unnecessary elements and simplify complex details. Remove backgrounds, boost contrast, and ensure that key shapes stand out. Many digitizing programs allow you to resize and crop artwork to fit your intended embroidery area—always set these dimensions to match your garment or product.

Remember: intricate shading, thin lines, and tiny text often don’t translate well to thread designs for machine embroidery. Aim for bold, solid shapes and avoid excessive detail. This not only makes digitizing easier but also ensures your finished embroidery looks sharp and professional.

2.2 Auto vs. Manual Digitizing: Choosing Your Approach

Once your image is ready, it’s time to digitize. Here, you face a fork in the creative road: auto-digitizing or manual digitizing.

Auto-Digitizing is perfect for simple logos, text, or basic shapes. Most embroidery software offers automated tools that convert your image into stitches with a single click. You can adjust parameters like stitch density and underlay to suit your fabric and style. Auto-digitizing saves time, but may struggle with intricate or highly detailed artwork.

Manual Digitizing is the go-to for complex designs or when you crave total control. This process involves tracing outlines, assigning stitch types (like satin for borders, fill for large areas, and running stitch for fine details), and layering stitches to add depth and texture. Manual digitizing lets you tweak every aspect—stitch direction, density, and color stops—ensuring your design stitches out exactly as you envision.

Many digitizers combine both methods: use auto-digitizing for simple sections, then manually refine tricky areas. The key is understanding the strengths of each approach and applying them where they shine.

| Stitch Type | Best For | Example Applications |

|---|---|---|

| Satin Stitch | Outlines, smooth curves | Logo borders, text |

| Fill Stitch | Large, solid areas | Backgrounds, bold motifs |

| Running Stitch | Fine details, thin lines | Veins, small text |

2.3 Stitch Parameter Optimization: Density and Underlay

Now, let’s get technical. Stitch parameters—like length, density, and underlay—are the secret sauce that determines how your design looks and feels.

- Stitch Length: Typically ranges from 2–5mm. Shorter stitches create smoother curves and finer details, while longer stitches are great for filling larger spaces efficiently.

- Stitch Density: Adjust this based on your fabric. Dense settings work well for thick materials (like denim), while lighter density prevents puckering on delicate fabrics (like silk or knits).

- Underlay: These foundation stitches stabilize the fabric and support the top stitches. Choose from center run, edge run, or zigzag underlays depending on your design and fabric type.

Varying stitch direction can mimic shading or add texture—diagonal stitches, for example, create subtle gradients. Always preview your design in the software’s simulation mode to catch potential issues before stitching.

Pro Tip: Test different combinations of stitch settings on scrap fabric before committing to your final piece. This hands-on approach helps you fine-tune for the best results.

2.4 Testing and Exporting Machine-Ready Files

Before you send your design to the embroidery machine, it’s time for a reality check. Export your digitized file in the correct format for your machine—commonly .DST, .PES, .EXP, or .JEF. Double-check your machine’s requirements to avoid compatibility headaches.

Transfer the file via USB, flash drive, or direct software connection. Load the correct thread colors and needles, then hoop your fabric securely (using a stabilizer if needed).

Always run a test stitch on scrap fabric. Watch for issues like thread breaks, excessive trims, or misalignment. If you spot problems, return to your software and tweak the design—adjusting density, underlay, or stitch direction as needed. Repeat this process until your sample stitch-out looks flawless.

Testing isn’t just a formality—it’s your best defense against wasted materials and disappointing results. Once you’re satisfied, you’re ready to embroider your masterpiece with confidence.

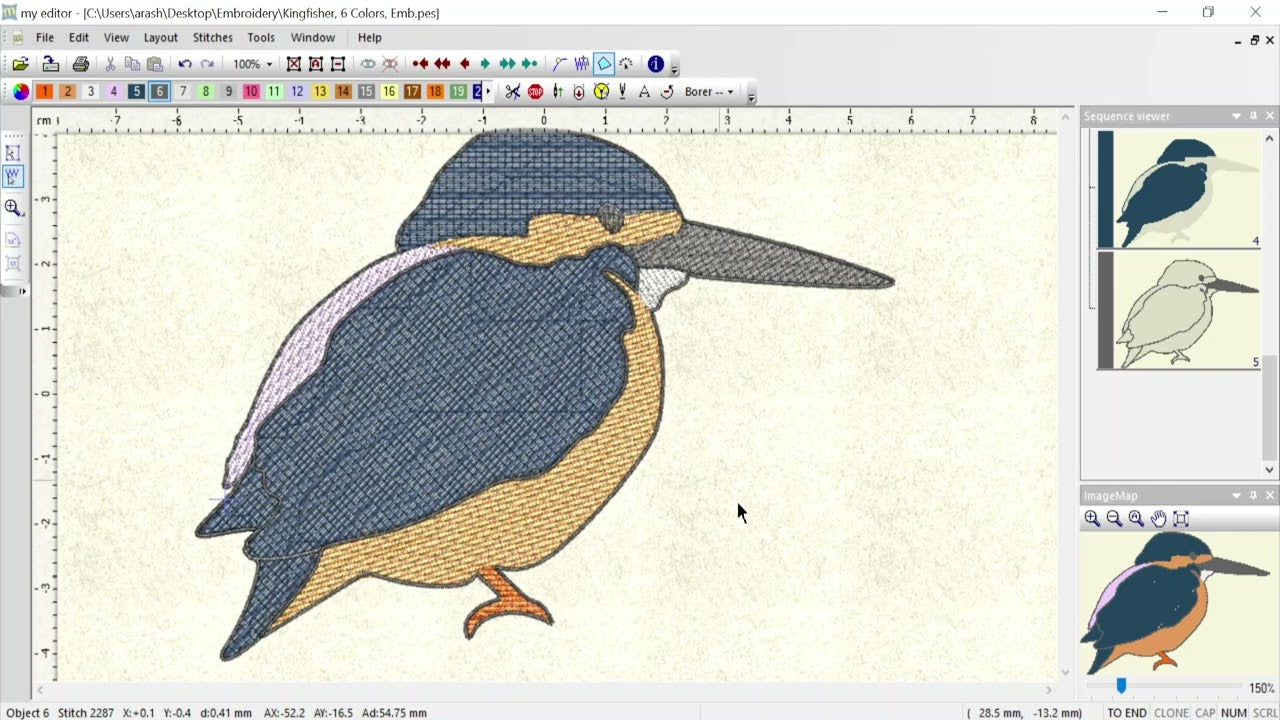

3. Software Showdown: Top Digitizing Tools Compared

Choosing the right digitizing software is a game-changer for embroidery success. Let’s break down the leading contenders and map out the best learning resources for each.

3.1 Hatch vs. Ink/Stitch vs. Wilcom: Feature Breakdown

When it comes to embroidery digitizing, three names stand out: Hatch, Ink/Stitch, and Wilcom. Here’s how they stack up:

| Software | Type | User Level | Price Range | Key Features |

|---|---|---|---|---|

| Hatch | Commercial | Intermediate | $199–$1,199+ | Tiered plans, auto-digitizing, CorelDRAW integration, advanced editing, machine compatibility |

| Ink/Stitch | Open-source | Beginner–Advanced | Free | Inkscape extension, basic editing, appliqué, community support, limited advanced features |

| Wilcom | Professional | Advanced | $4,000+ | Industry-standard tools, vector integration, color blending, monogramming, subscriptions |

Hatch is developed by Wilcom and offers a modular pricing structure, making it accessible for small businesses and serious hobbyists. Its auto-digitizing and CorelDRAW integration streamline the design process, while the digitizing software for embroidery and active forums provide robust support. The learning curve is steeper, but the results are worth it.

Ink/Stitch is a free, open-source extension for Inkscape. It’s perfect for those on a budget or just starting out. While it lacks some advanced features, it excels in customization and has a supportive GitHub community. Be prepared to learn Inkscape’s vector tools to get the most out of it.

Wilcom Embroidery Studio is the gold standard for commercial embroidery. Its advanced lettering, color blending, and seamless vector integration make it ideal for high-volume production. The trade-off? A hefty price tag and a complex interface.

Use Case Recommendations:

| Scenario | Recommended Software | Why? |

|---|---|---|

| Beginner hobbyist | Ink/Stitch | Free, minimal risk, great for simple projects |

| Small business | Hatch | Balances cost and features for scalable production |

| High-volume commercial | Wilcom | Industry-leading tools justify the premium price |

3.2 Free Learning Resources and Tutorial Pathways

No matter which software you choose, quality learning resources are your shortcut to mastery.

Hatch:

- Hatch Academy: Over 200 free lessons covering everything from basic digitizing to advanced appliqué.

- YouTube Guides: Search “Hatch embroidery tutorials” for step-by-step workflows and real-world tips.

Ink/Stitch:

- GitHub Community: Active forums and detailed documentation for troubleshooting and customization.

- Inkscape Basics: Master vector design with Inkscape before diving into Ink/Stitch.

Wilcom:

- Professional Workshops: Paid courses for advanced techniques like monogramming and color blending.

- Wilcom Support Hub: Official resources for mastering complex design elements.

Bonus: Many free tools and trial versions are available—Pixel-Stitch, Embroidery Tool Shed, and others—so you can experiment without a big upfront investment.

---

Ready to stitch your ideas into reality? The right preparation, software, and a bit of practice are all you need to create embroidery designs that truly stand out. Dive in, test often, and let your creativity lead the way!

4. Design Optimization Techniques for Professional Results

Creating embroidery machine patterns that look crisp, stitch efficiently, and minimize production headaches is both an art and a science. Let’s dive into the strategies that elevate your work from “just okay” to “wow”—all while saving you time and thread.

4.1 Simplifying Artwork and Color Reduction Strategies

Ever looked at a design and thought, “That’s gorgeous, but how will it stitch?” Professional digitizers know that less is often more. Here’s how to streamline your artwork for machine embroidery:

1. Minimize Complexity and Thread Changes Start by merging overlapping elements and eliminating unnecessary details. The fewer the color changes, the fewer stops your machine will make—meaning less downtime and fewer chances for errors. Group adjacent areas with the same color to keep the thread running smoothly. This is especially valuable in multi-needle machines, where every color change means a head movement and a pause in stitching.

2. Use High-Quality Artwork Begin with vector graphics whenever possible. Vectors (from tools like Adobe Illustrator) scale cleanly and make it easier for software to interpret edges and shapes. Low-res images often lead to jagged, blurry stitches—no one wants that.

3. Embrace Bold, Simple Shapes Avoid tiny text, thin lines, or intricate shading. Instead, opt for solid fills and clear outlines. For example, keep text at least 0.25" high and lines thicker than 0.05" for optimal legibility (as recommended by Printful and other industry guides).

4. Limit Your Color Palette Machine embroidery isn’t fond of gradients or excessive colors. Stick to a handful of contrasting shades. Not only does this reduce thread changes, but it also makes your design pop from a distance. When in doubt, test your color choices on fabric samples—thread and fabric can interact in surprising ways.

5. Prepare for Color Conversion When exporting to machine formats like DST or PES, be aware that color profiles may shift. Always double-check your thread chart and make manual adjustments if needed to ensure your stitched result matches your original vision.

Real-World Example: Print-on-demand platforms like Printful and Printify recommend using clean, solid shapes and avoiding photographic images or distressed textures. Their guidelines echo what pros know: keep it simple, scalable, and bold for the best results.

By focusing on clarity and efficiency in your artwork, you’ll set yourself up for embroidery success—less thread waste, faster production, and a design that shines on any garment.

4.2 Stitch Path Engineering for Efficiency

Here’s where the magic of digitizing really happens: stitch path engineering. Think of it as choreography for your embroidery machine—every move counts, and wasted motion adds up fast.

1. Reduce Jump Stitches Jump stitches are the “dead air” of embroidery: the needle lifts, moves, and drops again, leaving a loose thread to trim later. Too many jumps slow down production and create extra cleanup. Instead, use running stitches to connect isolated elements—especially when those stitches can be hidden under other parts of the design. For example, connecting two blueberries in a motif with a hidden running stitch is much faster than letting the machine jump, cut, and restart.

2. Sequence for Success Always embroider background elements first, then layer foreground details. This prevents fabric distortion and ensures everything lines up. In your digitizing software (like Hatch), set start and stop positions so the needle’s path flows logically from one area to the next. Preview the stitch sequence and adjust as needed to minimize unnecessary movement.

3. Optimize Color Order On multi-needle machines, align your thread colors in the same order as they appear in your design. This simple step can dramatically cut down on head movement and color change time. If you’re running a big batch, this trick alone can shave hours off your production schedule.

4. Leverage Software Tools Most modern digitizing programs let you manually adjust start/stop points and stitch order. Use these features to engineer the most efficient path—just like plotting the shortest route on a road trip.

YouTube Insight: A popular video on embroidery optimization demonstrates how moving start and stop points in Hatch software can eliminate unnecessary jumps. By strategically placing these markers, you guide the machine to stitch continuously, reducing both time and thread waste.

Key Takeaways:

- Replace jumps with running stitches wherever possible.

- Sequence your design logically: backgrounds first, details last.

- Align thread colors and machine needles for minimal movement.

- Preview and tweak your stitch path in simulation mode before stitching.

By mastering stitch path engineering, you’ll not only speed up your embroidery but also produce cleaner, more professional results—your machine (and your customers) will thank you.

5. Fabric-Specific Adaptation Strategies

No two fabrics are created equal—and neither are their embroidery needs. Adapting your digitized designs for knits, fleece, or denim is essential to prevent distortion, puckering, or even needle damage. Here’s how to tailor your approach for flawless results on any material.

5.1 Hooping Solutions for Knits and Stretchy Fabrics

Knits and stretchy fabrics like spandex or fleece can be a digitizer’s nightmare, prone to distortion and shifting. But with the right strategies, you can achieve crisp, stable embroidery every time.

1. Stabilizer Selection

- Cut-Away Stabilizers are your best friend for knits and fleece. They provide lasting support and prevent fabric movement during stitching.

- Water-Soluble Toppers help keep stitches crisp on textured surfaces like fleece, stopping threads from sinking into the nap.

- Avoid Tear-Away Stabilizers for stretch fabrics—they just can’t hold things steady.

2. Adjust Stitch Parameters

- Reduce Stitch Density: Lighter density prevents puckering and lets the fabric retain its stretch.

- Shorten Stitch Length: Shorter stitches improve stability and reduce the risk of skipped stitches.

3. Design Modifications

- Choose Lightweight Designs: Outline stitching and simple linework work best for knits. Dense fills can cause distortion or even perforate the fabric.

- Match Appliqué Fabric: If you’re adding appliqué, use a fabric with similar stretch to your base material.

4. Needle and Thread Choices

- Ballpoint Needles: These minimize snagging and slipping on knits.

- Polyester or Metallic Threads: These offer both elasticity and durability, perfect for garments that move.

5. Pre-Treatment and Testing

- Pre-Shrink Fabrics: Wash and dry before embroidering to avoid surprises after the first wash.

- Test on Scrap: Always validate your settings on a sample before moving to the final piece.

6. Magnetic Hooping Systems—Featuring MaggieFrame

When it comes to hooping stretchy or multi-layered garments, magnetic hoops like MaggieFrame are a game-changer. Their powerful magnetic clamping system automatically adapts to varying fabric thicknesses, ensuring even tension without overstretching. This not only reduces fabric distortion and puckering but also speeds up the hooping process—saving you both time and headaches. MaggieFrame’s textured surface and wide contact area keep knits and fleece perfectly in place, making it an ideal solution for garment embroidery (excluding caps). MaggieFrame magnetic hoops help eliminate puckering embroidery machine for small business.

Quick-Release Hoops can also reduce prep time and operator fatigue, especially during frequent fabric changes.

Key Takeaways:

- Prioritize cut-away stabilizers and water-soluble toppers.

- Use lightweight, stretch-friendly designs.

- Leverage magnetic hoops like MaggieFrame for even tension and easy hooping.

By customizing your approach, you’ll minimize distortion and production downtime—no more wrestling with puckered knits or misaligned fleece!

5.2 Heavy Material Tactics: Fleece and Denim

Tough materials like fleece and denim require their own set of tactics to ensure your embroidery looks bold and lasts.

1. Stabilizer and Machine Settings

- Heavy-Duty Cut-Away Stabilizers: Layer them if needed to handle thick, plush fleece or dense denim.

- Moderate Density and Standard Stitch Length: Don’t overwhelm the fabric—let it breathe!

2. Design Selection

- Bold, Simple Motifs: Avoid small text or thin lines that can disappear into fleece or get lost in denim’s weave.

- Minimal Detail: Let the fabric’s texture shine through instead of fighting it.

3. Needle and Thread Choices

- Heavy-Duty Needles (e.g., denim needles): These can pierce thick layers without breaking.

- Polyester or Metallic Threads: Durable enough for heavy fabrics and repeated washing.

4. Underlay Variations

- Standard or Zigzag Underlays: These stabilize the design and prevent shifting, especially in dense areas.

5. Testing and Adjustment

- Test on Scrap: Always stitch a sample to validate your stabilizer, needle, and design choices.

Real-World Example: A PatternReview discussion highlights how embroidery machines can handle multiple layers of fleece with the right stabilizer and needle. Users recommend testing designs and using tack-down stitches for appliqué, ensuring everything stays put.

By following these tactics, you’ll conquer even the toughest materials—your embroidery will stand out, not sink in.

6. Troubleshooting Common Issues with the best embroidery machine

Even the best digitized designs can run into trouble on the machine. Thread breaks, puckering, and distortion are the usual suspects—but with a systematic approach, you can solve these issues and keep your embroidery running smoothly.6.1 Solving Thread Breaks and Tension Imbalances

Common Causes: - Improper Threading: Missed guides or tension discs. - Tension Imbalances: Upper thread too tight or bobbin too loose. - Damaged or Dull Needles: Burrs or the wrong size for your thread. - Low-Quality Thread: Old spools prone to splitting.

Solutions: - Re-thread the Machine: Carefully follow the threading path, checking every guide and tension component. - Adjust Tension Settings: Test on scrap fabric to balance upper and bobbin threads. - Replace Needles: Use new, embroidery-specific needles suited to your thread type. - Use High-Quality Thread: Avoid bargain-bin spools and always check for age or fraying.

Diagnostic Flowchart: 1. Thread break? → Check threading → Replace needle → Test tension → Swap thread. 2. Still breaking? → Slow down machine speed, especially for metallic threads.

Pro Tip: Change needles every 1–2 projects and clean your machine regularly to prevent lint buildup.

---6.2 Eliminating Puckering and Design Distortion

Puckering and distortion can ruin even the prettiest design. Here’s how to keep your fabric flat and your stitches sharp:

1. Hooping Techniques - Hoop Fabric Gently: Don’t overstretch—fabric should be taut, not distorted. - Use the Right Hoops: Magnetic hoops like MaggieFrame provide even tension across the fabric, reducing puckering and hoop burn. Their textured surface and powerful magnets keep garments stable, even during long stitch-outs.

2. Stabilizer Selection - Cut-Away Stabilizers: Best for dense stitching or stretchy fabrics. - Tear-Away Stabilizers: Use only on stable fabrics like cotton. - Float Extra Stabilizer: Place an additional layer under the hoop for lightweight or tricky materials.

3. Design Adjustments - Add Underlay Stitches: These stabilize large or complex designs, preventing puckering. - Balance Stitch Density: Too much density can cause fabric to bunch up; too little and the design looks sparse.

4. Alignment and Placement - Mark Fabric Center: Use your machine’s centering tools or physically mark the center before hooping. - Secure Stabilizer: Make sure it’s tightly attached to the hoop to avoid shifting.

5. Test, Test, Test - Always run a sample on scrap fabric to catch issues before working on your final piece.

MaggieFrame Advantage: By providing even, reliable tension and reducing operator error, MaggieFrame magnetic hoops help eliminate puckering and distortion—especially on garments where consistency is key. Their durability also means less waste and fewer replacements over time.

---By mastering these troubleshooting techniques and leveraging smart tools like MaggieFrame, you can tackle embroidery’s most common pitfalls with confidence. Smooth stitching, sharp designs, and happy customers—now that’s professional-grade embroidery!

7. Advanced Manual Digitizing Workflows

Ready to move beyond the basics? Advanced manual digitizing is where artistry meets engineering—where every stitch is intentional, every path is optimized, and your embroidery machine becomes an extension of your creative vision. Let’s unravel the critical techniques that set professional designs apart.

Stitch Path Optimization: Choreographing the Needle

Think of stitch path optimization as dance choreography for your embroidery machine. The goal? Minimize unnecessary jumps and backtracking, so your design stitches out smoothly, quickly, and with fewer thread breaks.

- Efficient Routing: Start by planning the most logical, continuous sequence between design elements. Automated software tools can suggest initial paths, but manual tweaks are often essential to avoid redundant retracing.

- Minimize Jump Stitches: Strategically connect elements with running stitches (hidden when possible) instead of letting the machine jump, which saves time and reduces post-stitch cleanup.

- Prioritize Stitch Direction: Align your stitches with the fabric grain—especially on stretchy materials—to prevent distortion.

- Layering Order: Always digitize underlay stitches first, then top stitches. This builds a solid foundation and ensures crisp, professional results.

Testing and Refinement: Never skip a physical test stitch. This is where you catch issues like dense areas causing fabric stress or details needing shorter stitches. Adjust density and stitch length as needed to achieve both beauty and durability.

Underlay Variations: Building a Strong Foundation

Underlay stitches are the unsung heroes of embroidery—they stabilize fabric, support top stitches, and prevent distortion. Advanced digitizers know how to tailor underlay to both design and material.

| Underlay Type | Best For | Stitch Direction |

|---|---|---|

| Running Stitch | Lightweight fabrics (e.g., cotton) | Parallel to top stitches |

| Fill Stitch | Heavy fabrics (e.g., denim) | Perpendicular to top stitches |

| Tie-Down Stitches | Complex, overlapping designs | Strategic placement to secure layers |

- Pull Compensation: Adjust stitch lengths to counter fabric stretch—especially important for knits or large, dense areas.

- Layered Underlay: For multi-layered or 3D designs, multiple underlay passes add structural support and prevent collapse.

Custom Lettering Creation: Precision in Every Curve

Manual digitizing shines brightest when it comes to custom lettering. Here, you control every nuance—kerning, curve, and stitch angle.

Step-by-Step Lettering Workflow:

- Outline Tracing: Use satin stitches for bold outlines, adjusting length for smooth, consistent coverage.

- Fill Application: For solid letters, fill stitches with variable density ensure even coverage without bulk.

- Detail Enhancement: Running stitches add serifs or texture, following the natural curvature of each letter.

Challenges and Solutions:

- Kerning and Spacing: Manually adjust paths to avoid gaps or crowding.

- Curved Letters: Use radial or circular stitch paths to keep curves smooth and avoid jagged edges.

Modern software offers pen tools for precise tracing and preview features to simulate the finished embroidery—so you can catch and correct issues before they reach the machine.

Integrating Advanced Techniques: The Hybrid Approach

Complex projects—think metallic threads, sequins, or intricate appliqué—demand a blend of automation and manual finesse.

- Hybrid Automation with the best embroidery digitizing software: Use auto-digitizing for base shapes, then manually refine details for maximum quality.

- Material-Specific Adjustments: Tailor stitch density and underlay for each fabric type, from stretchy knits to sturdy wovens.

- Layered Digitizing: For embellishments like sequins, separate stitch files ensure precise placement and flawless execution.

Trend Watch: The best digitizers are always learning—combining software advances with hands-on testing to push the boundaries of what’s possible.

---

Bottom line: Advanced manual digitizing is equal parts science and art. By mastering stitch path optimization, custom underlay, and precision lettering, you’ll unlock a new level of quality and creativity in your embroidery designs. Always test on fabric, refine your approach, and let your imagination lead the way.

---

8. Conclusion: Your Path to Embroidery Design Mastery

Embroidery digitizing is a journey—one that rewards curiosity, patience, and practice. By mastering both the fundamentals and advanced manual techniques, you unlock the power to turn any image into a stunning embroidered work of art. Remember to experiment with software, optimize your designs, and leverage free resources to keep learning. Every test stitch brings you closer to mastery—so keep creating, refining, and enjoying the process. Your next embroidery masterpiece is just a few clicks (and stitches) away!

9. Frequently Asked Questions (FAQ)

9.1 Q: What file formats do embroidery machines use, and how do I choose the right one?

A: Most embroidery machines accept formats like .DST, .PES, .EXP, and .JEF. The right format depends on your machine’s brand—always check your user manual or software export options to ensure compatibility.

9.2 Q: How can I simplify a complex image for embroidery digitizing?

A: Start by removing unnecessary details, merging overlapping shapes, and limiting your color palette. Use bold lines and solid fills, avoiding tiny text or thin lines that may not stitch well. Preview your design in embroidery software to catch potential issues before stitching.

9.3 Q: What’s the best way to test my embroidery design before final production?

A: Always run a test stitch on scrap fabric similar to your final material. Watch for thread breaks, puckering, or misalignment. Make adjustments in your digitizing software—like tweaking density, underlay, or stitch direction—then test again until you’re satisfied with the results.

9.4 Q: Do I need specialized software to create embroidery designs, or can I use general graphic design tools?

A: While you can create artwork in programs like Illustrator or Photoshop, you’ll need embroidery digitizing software (such as Hatch, Wilcom, or Ink/Stitch) to convert images into machine-readable stitch files. These tools let you assign stitch types, set parameters, and export in the correct format.

9.5 Q: Are there free resources or trial software for beginners?

A: Yes! Tools like Ink/Stitch (open-source), Pixel-Stitch, and trial versions of Hatch or Embroidery Tool Shed offer great entry points. Many also provide tutorials and sample files to help you learn the basics without upfront investment.

9.6 Q: How do I avoid puckering or distortion when embroidering on different fabrics?

A: Choose the right stabilizer (cut-away for knits, tear-away for stable fabrics), adjust stitch density for your material, and ensure even tension during hooping. Test your design on scrap fabric to catch and correct issues before working on your final piece.

9.7 Q: What’s the difference between auto-digitizing and manual digitizing?

A: Auto-digitizing quickly converts simple images into stitch files, ideal for basic shapes or logos. Manual digitizing gives you full control—letting you trace outlines, assign stitch types, and optimize every detail for complex or high-quality designs.

9.8 Q: How do I create custom lettering in embroidery designs?

A: Use your digitizing software’s lettering tools or manually trace letter shapes with satin, fill, and running stitches. Adjust kerning, stitch direction, and density for crisp, readable results—especially on curved or decorative fonts.

9.9 Q: What’s the best way to optimize stitch paths for efficiency?

A: Plan your design’s stitch sequence to minimize jumps and color changes. Connect elements with running stitches when possible, and align thread colors on your machine to match the order in your design. Preview the sequence in your software before stitching.

9.10 Q: Can I convert hand-drawn art into an embroidery design?

A: Absolutely! Scan your drawing, clean up the image, and import it into your digitizing software. Trace the outlines, assign stitch types, and adjust parameters to create a machine-ready embroidery file.